Nearly eight years after the largest man-made disaster in state history, the Tennessee Valley Authority is pioneering a ground-breaking new technology to store and contain coal ash.

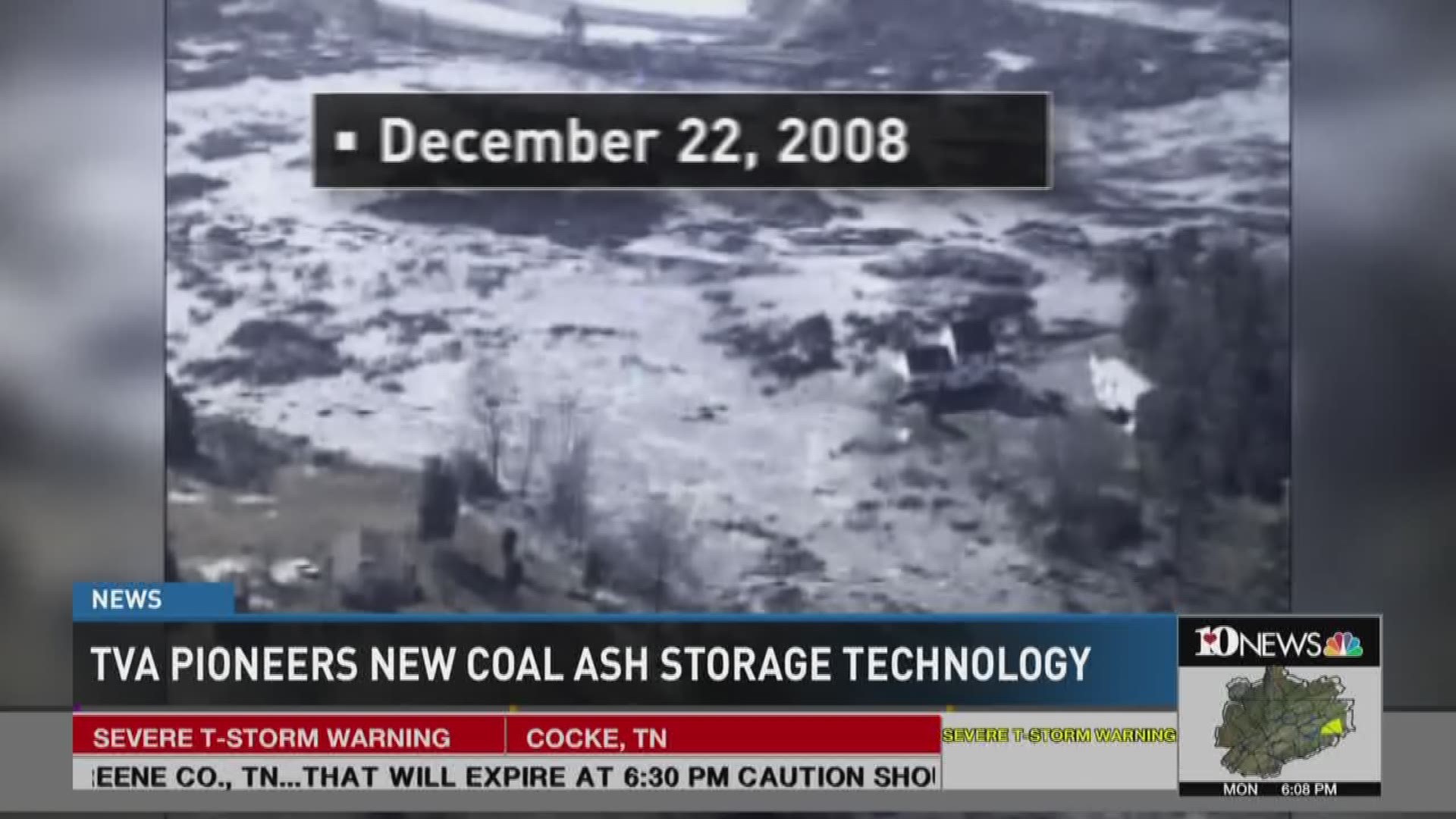

On December 22, 2008, millions of cubic yards of wet-stored coal ash broke through a dike at the Kingston plant, destroying three homes and damaging dozens more. Ash is the by-product of coal-fired power plants.

Since the breach, TVA has adapted a technique to better store ash, known as Intelligent Compaction. By using some new tools and highly sensitive equipment, the team can turn dusty coal waste in what resembles a parking lot.

“It’s state of the art,” said Jason Hill, the Risk and Quality Assurance program manager for TVA. “Nowhere else in the world is this happening? We’re saving rate-payers money by compacting material more than we normally would.”

Intelligent Compaction is a high-tech solution to the ongoing problem of safely storing ash. Across the entire system, TVA produces millions of tons of the dusty grit every year. This new technique makes storing it much simpler and safer.

“What we’re doing is getting a sense of the density of this material,” said Nick McClung, who also worked on the project for TVA.

By using a vibrating drum, crews help work the air and moisture out of the ash, creating a surface much like concrete. Highly precise sensors help them see which areas need more attention in the acres of ash – something previous technology did not allow.

“The goal is to get this as stiff and dense as possible,” said McClung.

The Kingston ash field is already 15 feet deep, and will eventually reach heights of 40 feet. McClung said Intelligent Compaction helps them make sure they’re maximizing their storage space, and guaranteeing its stability.

But safety is also a goal of the project. Since the 2008 spill, TVA has been transitioning all their plants to dry ash storage, so there’s no dike left to breach.

Knowing that, Wayne Rose feels much more comfortable living down river – he recently moved onto a lot that was nearly wiped away in the ash tsunami. After the cleanup process, it was sold at auction. Now, his backyard is all green grass and clear water.

“I looked around and said, ‘I have to have this house,’” said Rose. “I don’t believe I’ve seen a nicer view in Tennessee.”

He said he’s happy to hear about the new storage techniques.

“I do have confidence that they’re going to protect me from the same kind of thing that happened before,” he said.

It’s exactly what TVA leaders have been hoping for. Developing the technology cost millions, but in this case, they needed to spend money to save money.

“At TVA, it’s about saving rate-payers money,” said Hill. “That’s what we’re doing, reducing risk and saving money.”

He said they also plan to roll the tech out to the entire TVA system. It’s already operating at Bull Run. He believes it could become the industry standard for ash storage.

“As time goes on, we’re going to reduce cost,” said Hill. “Because we’re going to fine tune our operations.”